LOCTITE® 641TM Retaining Compound A controlled-strength retaining compound that is ideal for cylindrical parts that require

Retaining solutions - Henkel Adhesives

These different retaining compounds cover a wide variety of tolerances and applications for plant maintenance and assembly needs. Visit our e-Catalog to explore all the types of LOCTITE retaining …

Loctite@ Retaining Compounds Properties Chart Item Package PRODUCT Number Type & Size 1. 5,000 125 125 500 125 Semisolid 8,500 600 2,000 2,500 ,250 525 / 1,950 Thixotropic 250,000 / …

- [PDF]

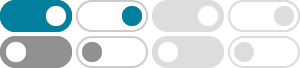

RETAINING COMPOUNDS

A high-strength retaining compound is recommended for applications that do not need to be disassembled or require extremely high torsional loads. If parts need to be taken apart for …

When to Use Which LOCTITE + Charts from Henkel | AIMS Industrial

Sep 23, 2025 · Refer to these charts, illustrations and references to know which Loctite product to use with various materials and surfaces.

LOCTITE® Retaining Compounds have very high compression strength, and prevent fretting corrosion. Retaining compounds are available in removable strengths for easier assembly.

Retaining Compound - Loctite Adhesive

LOCTITE Retaining Compound provides high-strength bonding for cylindrical parts such as bearings, bushings, gears, and shafts. They eliminate loosening, fretting, and corrosion by filling gaps and …

LOCTITE Retaining Compounds - Henkel Adhesives

LOCTITE retaining compounds are available in many different compositions and strengths to cater to a wide range of industrial applications. These different retaining compounds cover a wide variety of …

LOCTITE® Retaining Compounds secure bearings, bushes and cylindrical parts into housings or onto shafts. They achieve maximum load transmission capability and uniform stress distribution and …

Loctite Retaining Compounds Explained: How to Choose the Right …

Follow our guide for selecting the right Loctite retaining compound to ensure maximum durability, high-temp performance, and precise gap filling from the experts at Silmid.